Search the whole station Products News

HIOKI IN-CIRCUIT HiTESTER 1220 has been available for more than ten years, and the official has stopped updating it, and FA1220 was derived in 2021. At present, some enterprises in the market are still using HIOKI IN-CIRCUIT HiTESTER 1220 and have a large number of test fixtures suitable for HIOKI 1220. In order to save costs, it is hoped that new equipment can be compatible and share these existing fixtures, so as to avoid re-investing a lot of money to purchase new fixtures due to equipment replacement. PTI-816S Inline tester can realize the conversion between HIOKI 1220 fixture and program, reduce the equipment cost of enterprises, and improve the test coverage and efficiency.

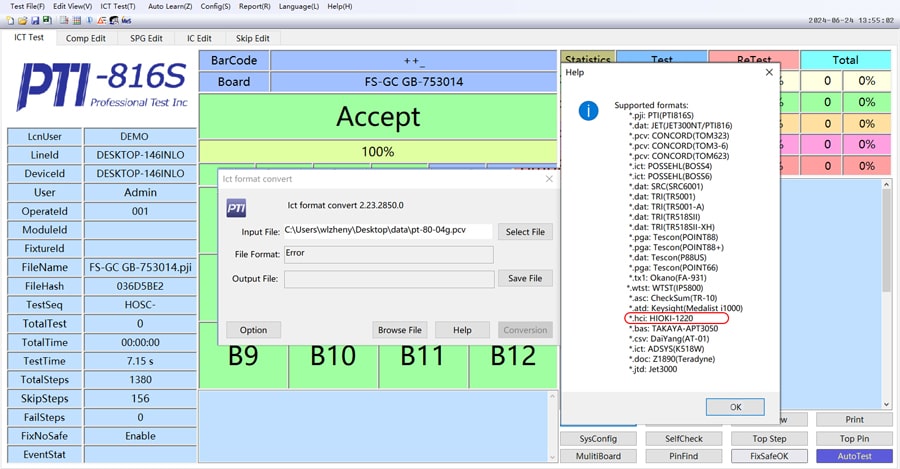

transformation process

HIOKI IN-CIRCUIT HiTESTER 1220 system has a history of more than ten years. The software runs in MS-DOS environment and does not provide much flexibility or function. For example, the system does not support 3rd software integration and interfaces based on Microsoft Windows windows, which are more user-friendly.

Modern test systems need to be flexible so that users can deploy in different environments and requirements. It needs to be compatible in order to extend the system functions with external third-party hardware. It needs to be fast, accurate and efficient.

Fixture sharing

The PTI816S is designed with full consideration of compatibility. By optimizing the fixture interface and signal transmission, it can be directly compatible with the testing fixture of HIOKI 1220. We have carried out a comprehensive inspection and adaptation of the fixture to ensure that it can be tested stably and accurately when used on PTI816S, thus avoiding the test error and equipment failure caused by the incompatibility of the fixture.

Cable conversion

In view of the inconsistent transmission of some signals, we specially designed and made the conversion cable. These conversion cables can accurately convert the signal on the HIOKI1220 fixture into a signal that can be recognized by PTI816S. Both HIOKI 1220 and PTI816S adopt 64PIN cables, which ensures the integrity and stability of the test signal and the solid and reliable physical connection between the fixture and the new equipment.

In order to realize the rapid conversion from HIOKI 1220 test program to PTI816S, we developed a special program conversion tool. This tool can read the program files of HIOKI 1220, and automatically transform and optimize the test steps, parameter settings, signal definitions and other contents in the original program according to the programming specifications and grammar requirements of PTI816S, and generate a test program suitable for PTI816S.

According to the performance characteristics of PTI816S, some test parameters and algorithms in the program are optimized to further improve the test speed and efficiency and ensure the reliability and consistency of test results.

By replacing HIOKI 1220 with PTI816S, customers have successfully solved the problems such as equipment aging, difficult maintenance and upgrading, and at the same time realized the expansion of testing functions and greatly improved the testing speed, effectively improved the production efficiency and product quality, and provided strong support and guarantee for customers’ production development.

0

0