Search the whole station Products News

functional testing

Project Case

With the development of LCD in the direction of large size, thinness, low power consumption and high resolution, the size and thickness of glass substrate and related optical components are gradually increasing, which greatly increases the probability of various display defects in LCD screen. Traditional artificial vision inspection methods are easily influenced by subjective factors of inspectors and external environment, so it is difficult to ensure product quality and the inspection efficiency is also low. Therefore, equipment for automatic photo inspection and pixel-level defect identification is designed.

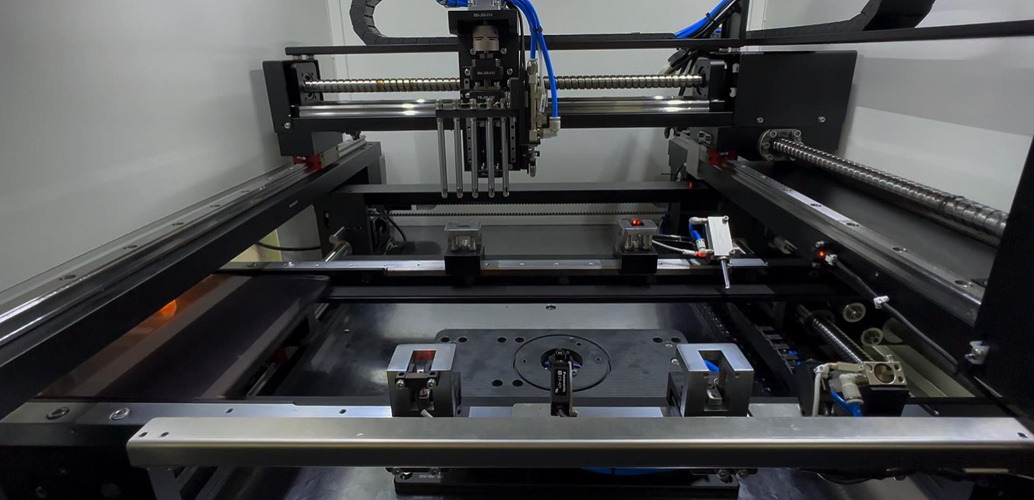

In this project, a manipulator or a person is responsible for taking and placing the board to be tested, putting the product (touch screen) on the docking station and automatically entering the test area. In the test area, the communication connector is automatically inserted into the socket of the touch screen to complete the line connection. After the line connection is completed, all test items are automatically completed by program control, and the test results are transmitted to the manipulator through I/O or network port communication after the test is completed. According to the test results provided by the test equipment, the manipulator places the good products and the bad products in different places.

Manipulator/Manual discharging starts the test → Software initialization → Code scanning → Complete the board feeding → Power on the product → Start test (Visual and tactile) → Complete test → Discharge the board

The X/Y/Z platform is stable, and with the help of the finger cylinder, the touch of the screen is stable. Touch detection is carried out with one touch pen and five touch pens.

The track is compatible with multiple screens and can transmit stably.

The foolproof mechanism is stable and can check whether the screen is flat and stable.

The connector is automatically inserted, and the power supply is stable.

Scheme advantage

| Contrast dimension | Original customer information | PTI-500XV tester |

| Test mode | Manual manual test | Automatic test |

| Test efficiency | 10min | 2min |

| Artificial | Manual test and manual record | Manipulator load and unload |

| Test item | Single test | Fusion function test |

Equipment shot

0

0