Search the whole station Products News

functional testing

Project Case

Automobile suspension controller is the core component of automobile suspension system, which is like the “brain” of suspension system. Its main function is to accurately control the suspension system according to the driving situation of the vehicle and the operation of the driver. It receives signals from various sensors. Based on the received signals, the suspension controller calculates appropriate control strategies through complex control algorithms, and then sends control instructions to the actuators of the suspension system. Actuators generally include solenoid valves, motors, etc., which are used to adjust the damping, stiffness and body height of suspension. For example, when the vehicle is driving at high speed, the controller will increase the damping of the suspension to improve the stability of the vehicle; When the vehicle passes through the bumpy road, it will adjust the damping and stiffness according to the degree and frequency of road bumps, so as to keep the vehicle comfortable.

It is of great significance to carry out ICT (on-line test) and FCT (function test) for automobile suspension controller. ICT testing aims to ensure the basic circuit function of the controller circuit board, improve the initial quality and reliability of the product by detecting the welding quality of components and ensuring the accuracy of component parameters, and lay the foundation for the realization of subsequent functions. FCT test focuses on verifying the functional realization of the controller under actual working conditions, simulating various driving scenarios, ensuring that it can correctly process sensor signals and output accurate control signals to adjust suspension parameters, and ensuring driving safety and comfort. At the same time, FCT testing can also ensure the consistency and compliance of product performance and meet the strict quality and safety standards of the automobile industry.

Test requirements

Detailed scheme/equipment structure

Composition of the project plan

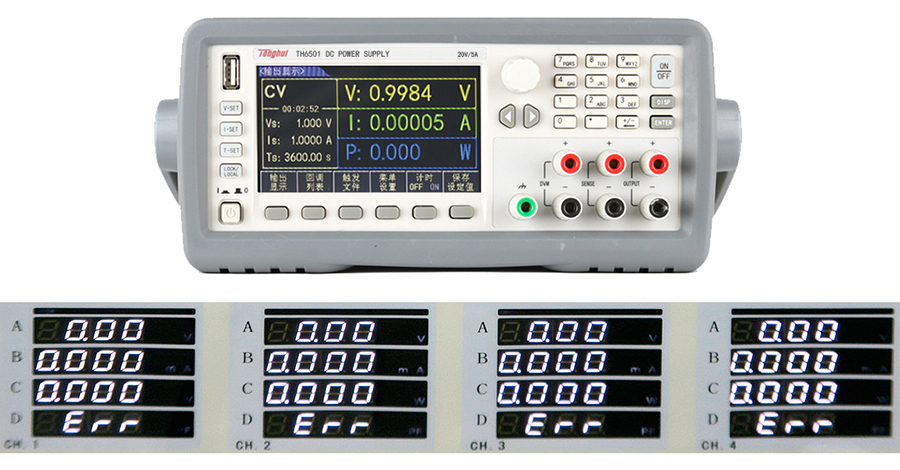

Through the detailed interpretation of the test requirements, the project chooses PTI-300 test system, and the whole project scheme consists of instrument cabinet, test table and functional fixture.

The equipment supplies power to the load with programmable voltage, phase and frequency through DC power supply, the industrial computer controls the computer, the electronic load protection function simulates the load situation, and the 4-channel power meter displays the instantaneous voltage, current and power. The customer suspension is placed in the cabinet of the test table, and the pneumatic test fixture is placed on the desktop.

Test content:

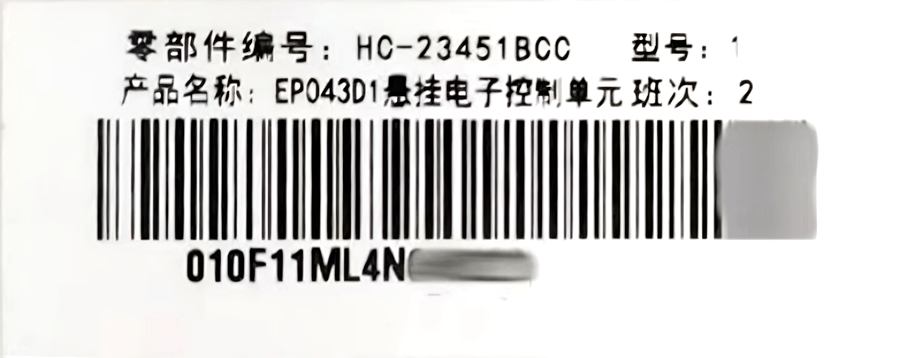

Write the read assembly SN code and batch number into PCBA.

Test method:

The generated serial number is transmitted to the CPU according to the coding principle (year, month and day+serial number information), and the CPU transmits a coding information to compare with the generated serial number. After all functional tests PASS, the serial number will be printed successfully.

Test content:

Test and drive the left front, left rear, right front and right rear solenoid valves with stable output of 1.6A and 160mA respectively, and write the results into MCU.

Test method:

Read the current under standard load with ammeter.

Equipment shot

0

0