Search the whole station Products News

functional testing

Project Case

For a long time, the application of the car has been called the greatest invention, and then the part of the car that can carry people. The seat has become crucial. In addition to ensuring that the driver’s position and visual field are suitable and comfortable, more attention should be paid to the flexibility and safety and reliability of seat adjustment. Therefore, relevant manufacturers need high-precision functional testing to maintain these characteristics. FCT makes the seat control more in line with the driver’s personal operation.

Test requirements

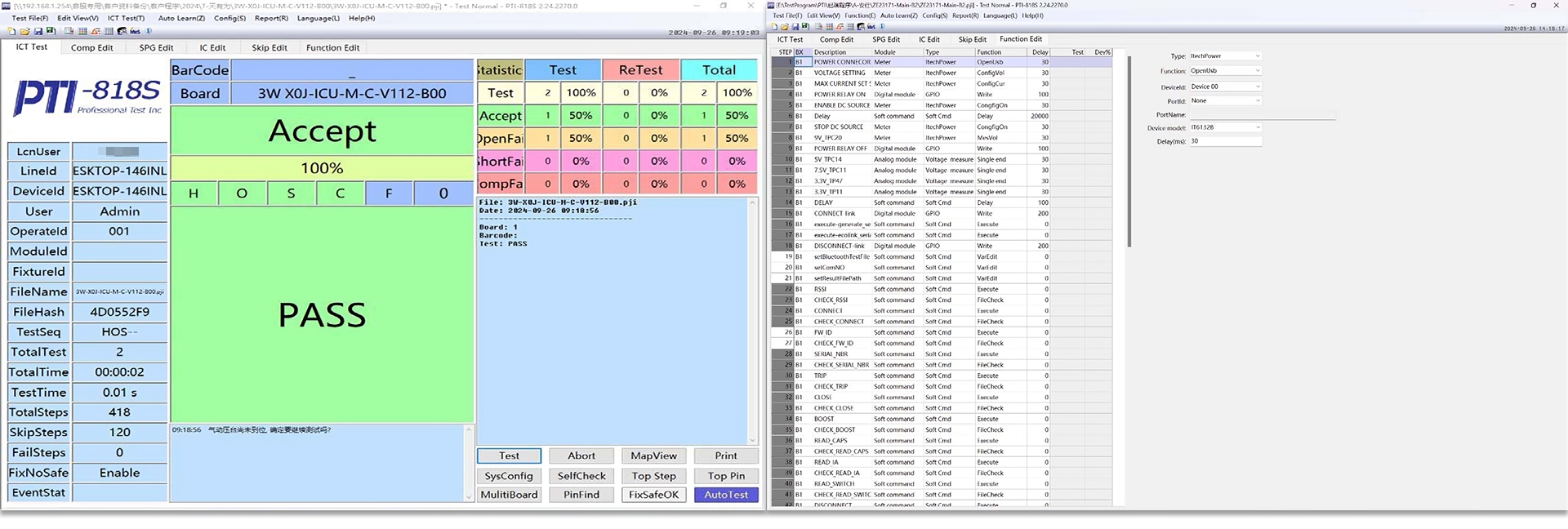

Based on customer testing requirements, we use PTI-818S equipment, which has all the functions required for testing, thus increasing the maturity, stability and rapidity of making the scheme.

PTI-818S has complete functions and small size. It uses USB communication, an integrated test solution with high cost performance, and static test and functional test to complete all electrical performance tests in one stop. It is the best choice for customers to ensure quality and improve efficiency.

Scheme characteristics

| Project | Original basic tester | PTI-818S FCT tester |

| Detection mode | Manual board placing detection | Full-automatic board release detection |

| Efficiency | Manual inspection (one board and one inspection) | Simultaneous detection of multiple jigsaw puzzles |

| Artificial | 6 worker/1 production line | 1 worker/1 production line (Only through software control) |

| Detection requirement | Only bad conditions can be detected | Bad situation+function test |

0

0