Search the whole station Products News

functional testing

Project Case

Intelligent infrared hand sanitizer, as an intelligent device combining household appliance technology and daily chemical products, is widely used in home environment, medical institutions, public places (shopping malls, hotels, airports, stations, schools) and other fields because of its advantages of automatic liquid discharge, no contact and reduction of cross-infection risk. In order to ensure the normal use of the product, it is necessary to carry out a series of functional tests on its main control board.

Test requirements

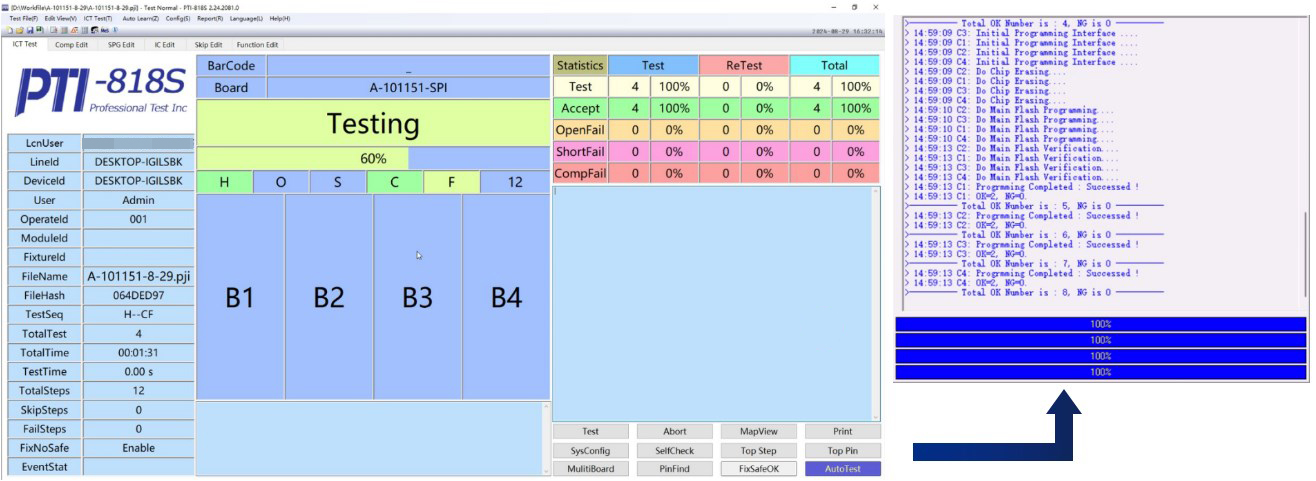

Through the detailed interpretation of the test requirements, PTI company’s current standard equipment PTI818S meets all the required test functions, so this project uses PTI818S for scheme implementation. The scheme flow chart is as follows:

The project consists of four consecutive pieces, each PCBA has a key, and the fixture receives software commands to control the four pillars through electromagnetic valves, simulating the physical pressing of the key, and making comprehensive judgment of the system.

Through the stop mechanism on the fixture, the real use scene is simulated, the infrared sensing function is automatically triggered, and the data is transmitted to the equipment for comprehensive judgment.

The chip model that needs to be burned in this project is msp430g2452. In this scheme, the programming device is plugged into the 818S test equipment, and the burning instruction is called to burn the program.

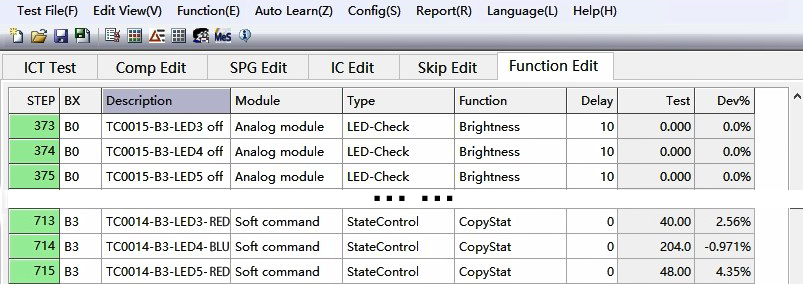

PTI-LED module mainly detects the brightness, color (three primary colors: red, green and blue), brightness contrast and flicker frequency of LED. Its principle is that the light from the light source to be tested is filtered and transmitted to the LED testing module through optical fiber, and then the data is collected to the equipment to realize automatic testing. In the project, there are 12 lights in 4 consecutive pieces, and 12-channel LED test module is optional (support customization).

PTI818S supports the generation and export of test LOG data, which is convenient for data summary and later traceability, and supports the docking with MES system in the enterprise to realize intelligent management of the whole process.

| Contrast dimension | Original customer information | After the implementation of PTI test scheme | Result |

| Space utilization ratio | ICT+ Burn+FCT | PTI-818S | From three stations to one station |

| Human cost | 3 | 1 | Save 2 labors |

| Test efficiency | 1min | 25s | Test efficiency is improved by 4 times |

| Production efficiency | 80 | 480 | UPH increased by 6 times |

| Quality control | Multiplex stations are prone to errors | The process is simplified and the degree of automation is high | Reducing human intervention is conducive to improving the stability and consistency of product quality |

| Flexibility and scalability | Multiplex combat effectiveness operation | Integrated chemical station, universal test platform | The equipment is universal and easy to adjust and optimize |

0

0